Easy to learn and operate

Accurate

Reduces man power

Cut costs and increase productivity

System Features

Design

Precision Patented linear guidance system with precision high pitch ground ballscrew ensures accurate cutting to

(+/-0.005/60”) (0.05mm/300mm)

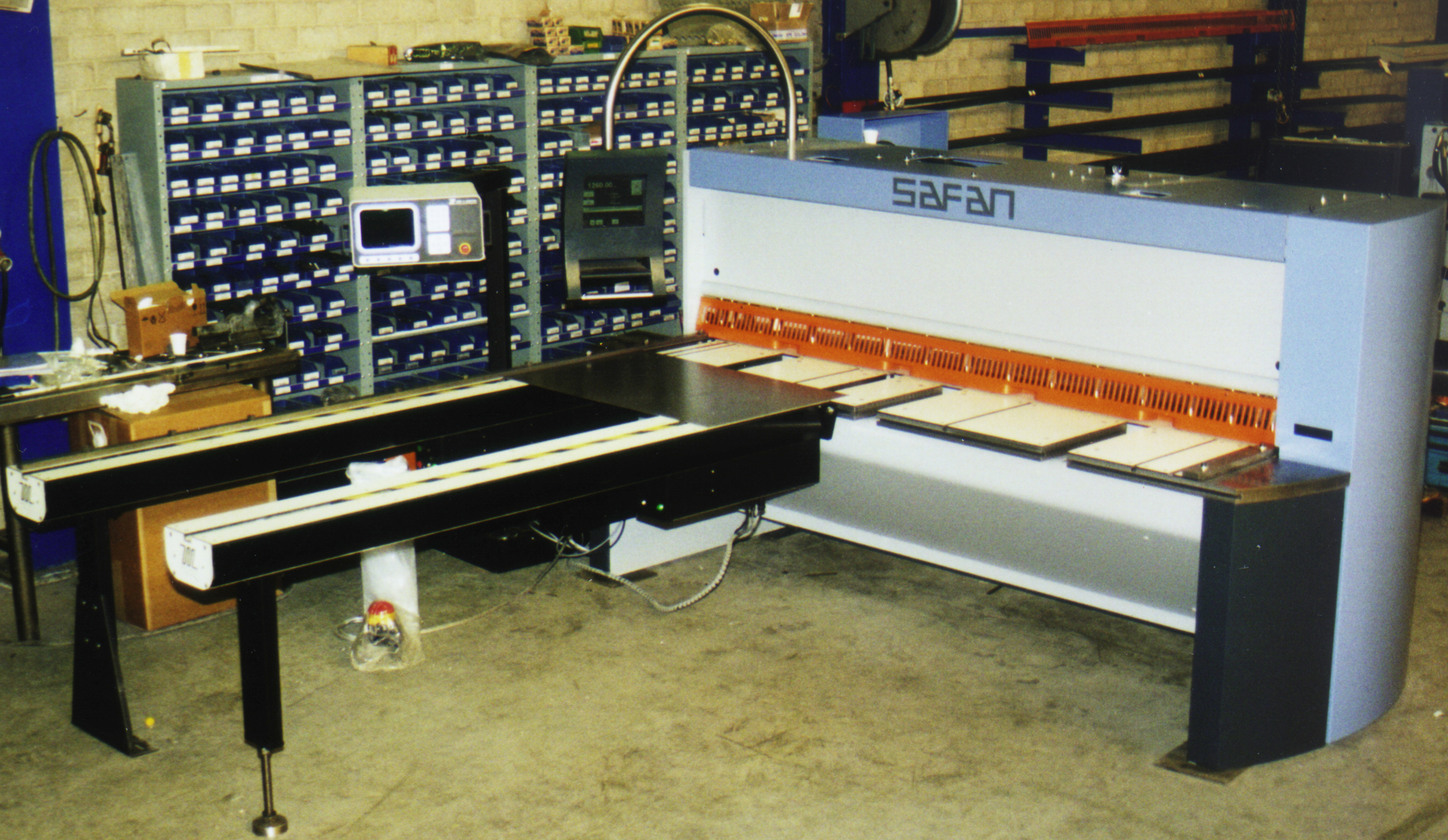

Ball Transfers

Ball Transfers to help protect expensive material when moving. Also makes one man operation a breeze.

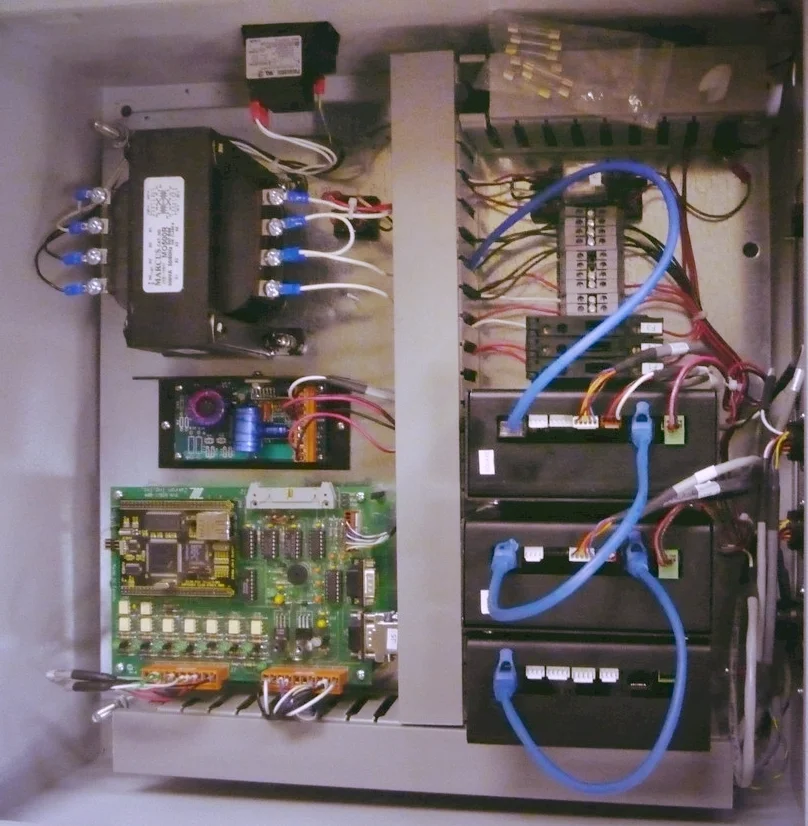

Electronics

Zakron designs most of the electronics in all our systems. Including our new digital servo amplifiers, power supplies and CPU card. This helps ensure that spare parts will be available in the future to the customer.

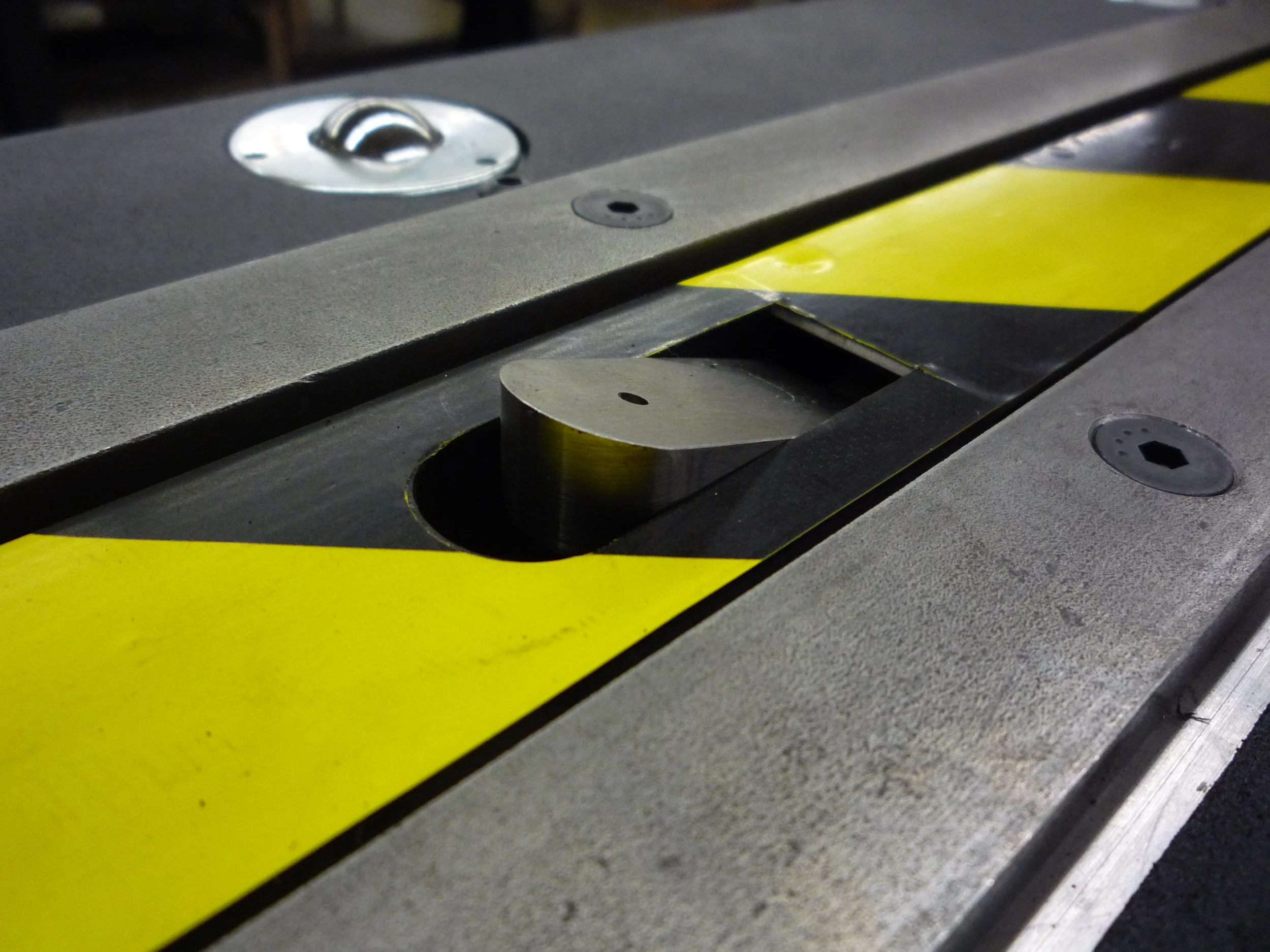

Hardened Finger Stops

Software selectable spring loaded pneumatically operated retractable finger. Fully hardened to 50 Rockwell.

Custom Aluminum Extrusion

Custom design 6061-T6 extruded aluminum frame provides rigidity for internal components and linear positional accuracy.

Get a Quote

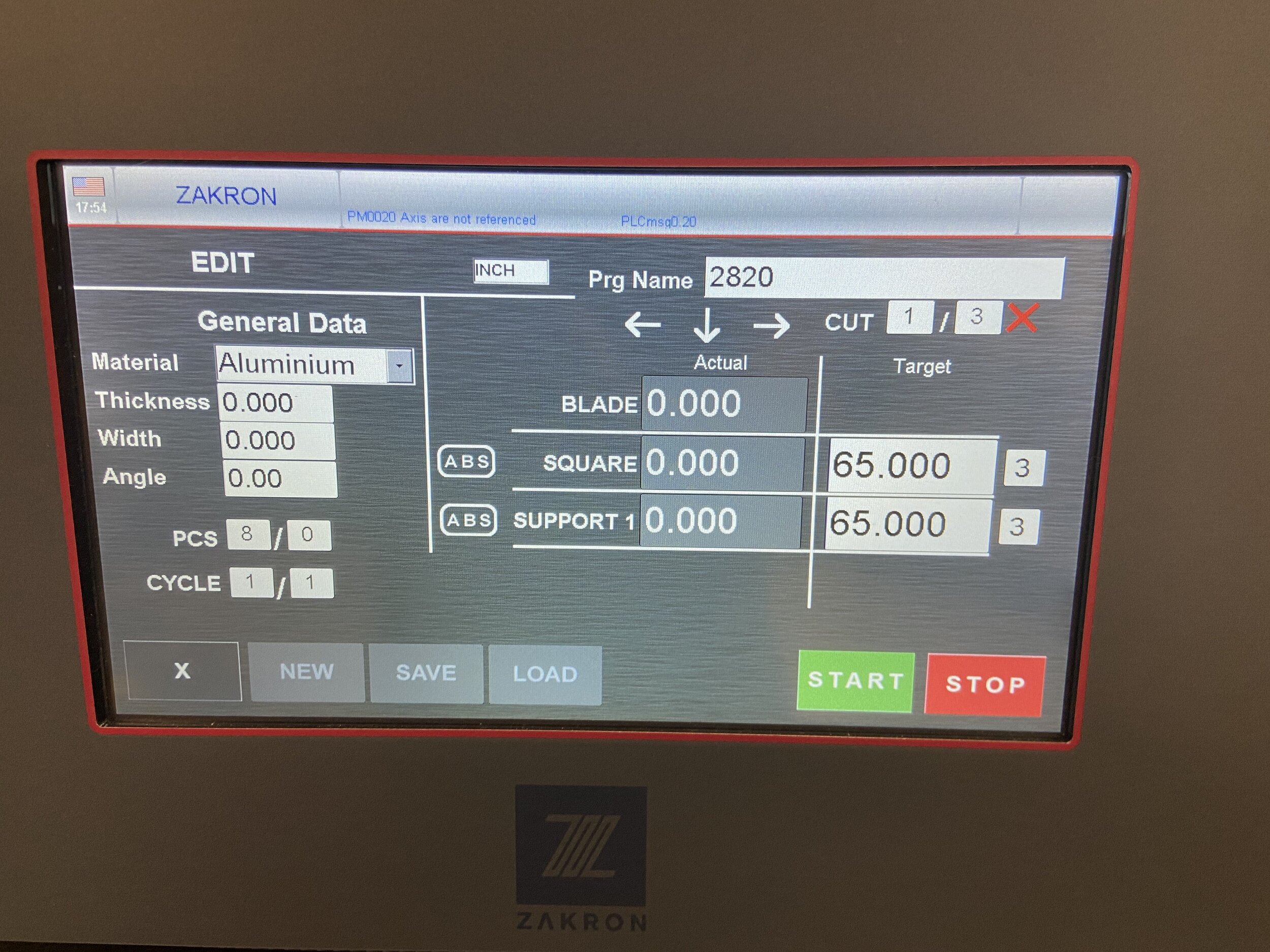

CNC Touch Screen

10” CNC Shear Touch Screen

Sheargauge EDIT interface

10" CAPacitive Touch Screen

Easy to read touch screen interface for clear navigation and usability.

Screen Modes

Automatic, Manual, Edit, Calibrate, Directory, Communications

Offline Programming

Optional offline programming via PC

Realtime Position Feedback

On all calibrated axis

Parts Counter

32 Absolute Cuts per job

Absolute or Incremental operating modes

For various cutting operations

Options

Barcode Input

Use a barcode to program the control and move the gauge arms.

Up to 4M Long

Gauge arms can be made up to 4m long for large scale accurate shear processing.

Fully Automatic Mode

With optional software the gauge can be made to run in full automatic mode receiving a drip feed of the programs from a PC.

UHMW Top Plate

Used for pre-finished material like stainless steel or pre painted blanks.

Moveable or Swing out Support Arms

The support arms can be mounted to either swing out of the operators way or be moveable along a track to increase floor space.

Warranty

Full 1 Year Warranty

Standard factory warranty. Call for more details.